Our Capabilities

Our Core Capabilities

Our core capabilities are centred around injection mold building, production and prototype tool building for vacuum forming, secondary tools and check fixtures for both North America and International Markets. We also have complete in house mold-flow analysis and CAD design.

Capabilities

Injection Mold Building

Secondary Tooling and other Tool Building

Other Core and Complimentary Capabilities

CAD/ CAM

Compression Tools

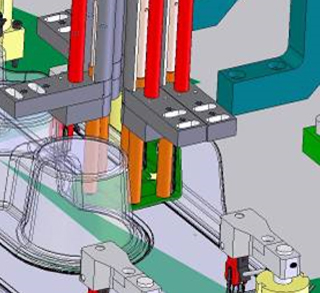

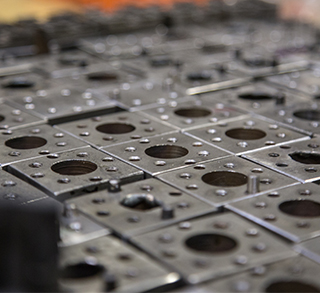

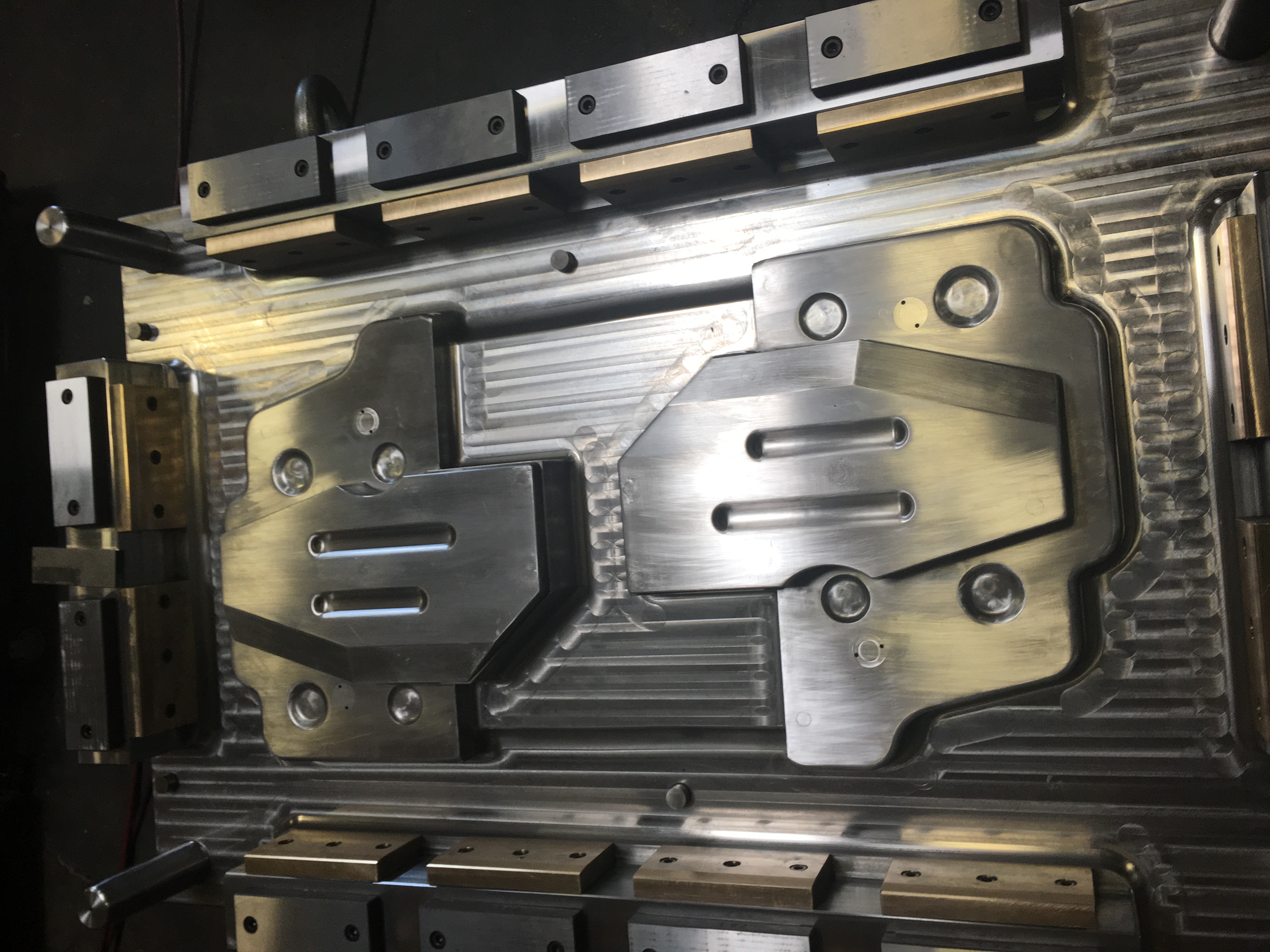

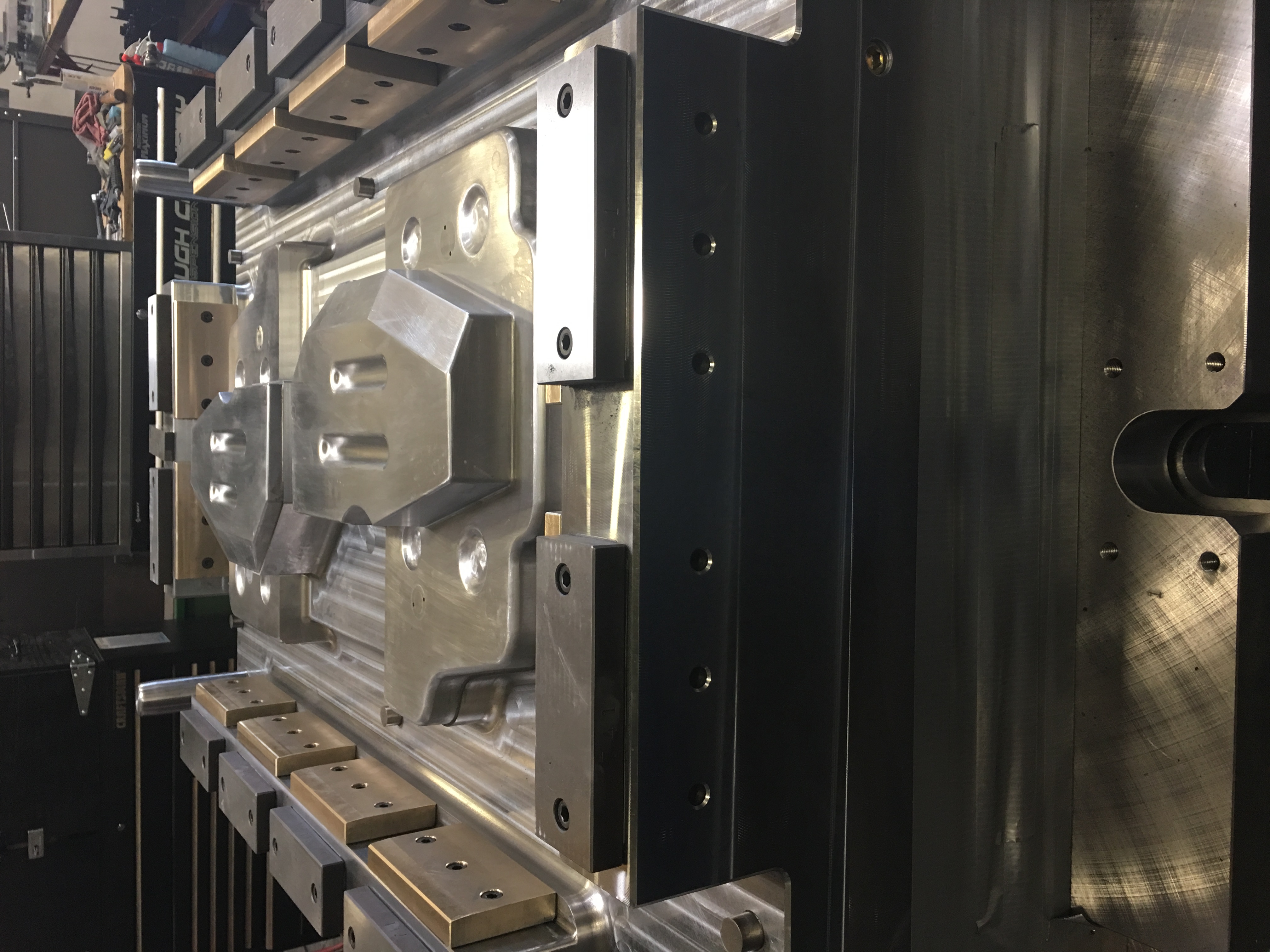

Injection Mold Building

Injection Mold Building

In addition to our offshore resources we also can build wide range of tool domestically as well as support any maintenance and engineering change requirements. All of our domestic builds are in tune with today's competitive market and can provide lower cost for tools wile maintaining short deliveries and high quality.

- Injection Mold Building and Assembly

- Large-Scale Molds

- Multi-Shot Molds

- Insert Molding

- In-Mold Decorating With Films

- Domestic and Offshore Tool Building

- Gas-Assist Injection Molding

- Aluminum and steel molds

- Prototype molds

Secondary Tooling and other Tool Building

Secondary Tooling and other Tool Building

TMMS can also provide tooling for your secondary operation needs. Whether you need clips put on parts or heat steak welding we can provide you with an affordable solution. All secondary tooling comes complete in a sturdy, easily movable and easily adjustable aluminum and steel constructed frame, PLC controller with light bingo board, Banner Opto touch machine execution and are PSR & CSA compliant.

- Thermoforming Tools

- Attach Clips and Fasteners

- Heat Staking

- Vibration Welding

- Laminating

Other Core and Complimentary Capabilities

Other Core and Complimentary Capabilities

Checking fixtures and CMM fixtures are essential to your plastic part production possess. They help ensure that the injection moulding machine and process are repeating and build consistent parts. TMMS has several years experience in managing the build of gauges and fixture for a wide range of use. We use several resources to ensure all the needs of the customer are met.

- Gauge and Fixture Tooling

- Rapid Prototyping

- Mold Flow, Cooling and Warp Analysis

- Process Controls with Customized Process Spread Sheets

- Research and Development

CAD/ CAM

CAD/ CAM

At TMMS Inc. we offer the following CAD/CAM capabilities

- Catia

- Pro E

- Cad-Key

- UG

- Moldflow / Mold cooling & warp – Silver Certified

- Solid Works

- Product design optimization for manufacturing

Compression Tools

Compression Tools

At TMMS Inc. we offer Compression Tooling capabilities

Focus, enthusiasm and sincerity with our customer service.

Our friendly and professional program managers are standing by. Give us a call today.